Summary

I managed the transformation of a sculpture studio into a digital fabrication studio. In the face of ambiguity, I successfully brought in and implemented multiple technologies, developed organization systems, researched and instilled safety protocols, designed and hosted workshops on material experimentation, and assisted hundreds of people with their projects.

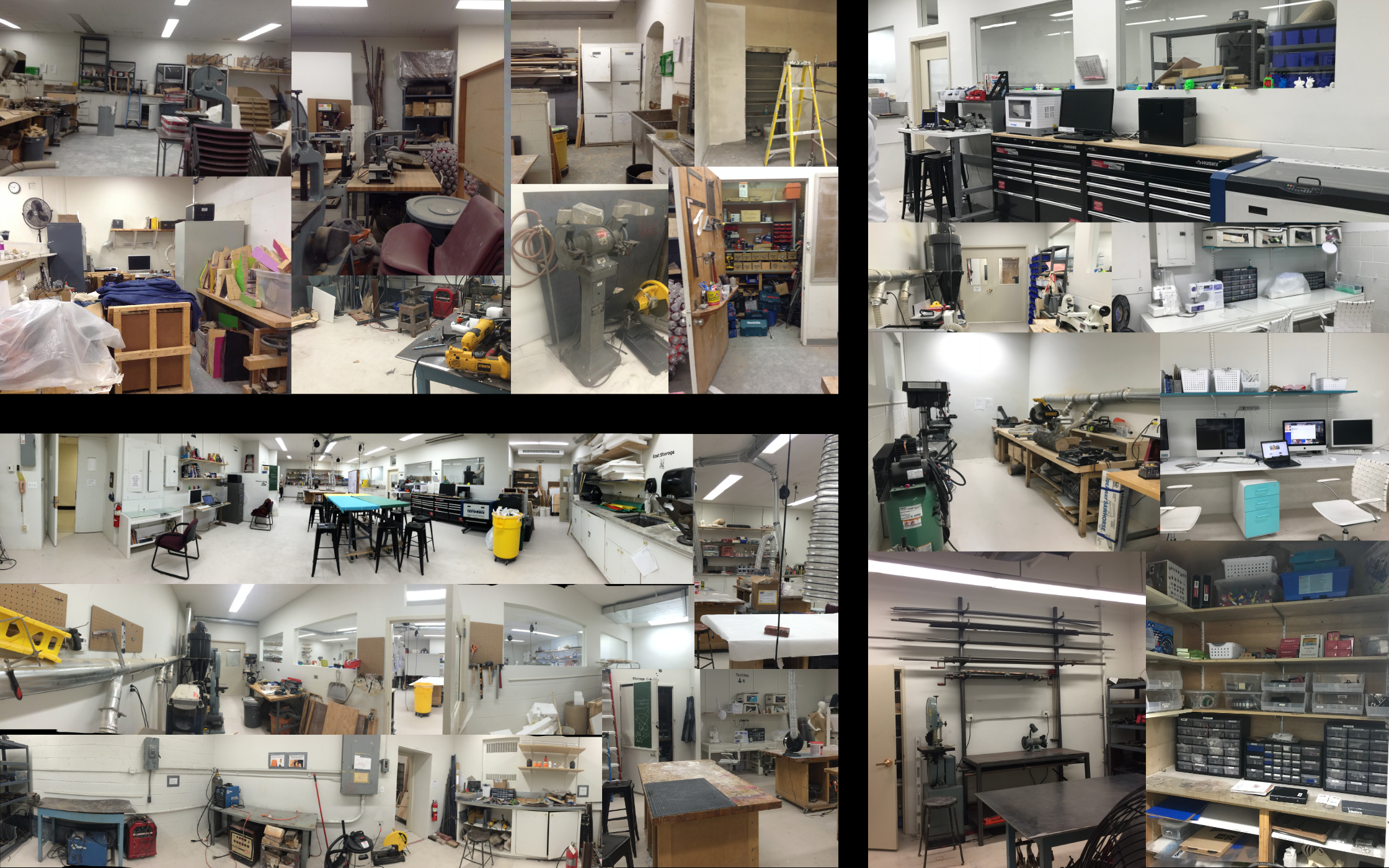

Blank Slate

In tandem with new creative technology initiatives and a general push for greater technology literacy among artists and art educators, the Art and Art Education program at Columbia University sought to transform their largest studio into a digital fabrication studio, akin to makerspaces and other digital fabrication spaces in educational settings.

When I first arrived, the studio was focused on woodworking, sculpture, and metalworking and had zero digital fabrication technology. The space had collected many found materials over the decades of former faculty and students using the space including giant rocks, tree trunks, all loosely organized. Many of the organizational furniture was makeshift and materials and functions were overlapping. It was a challenge to decide what to keep at first especially since the new space was supposed to be open to the possibilities of any new person; furthermore, figuring out ways to reuse materials and stay low budget as an educational institution was a boon.

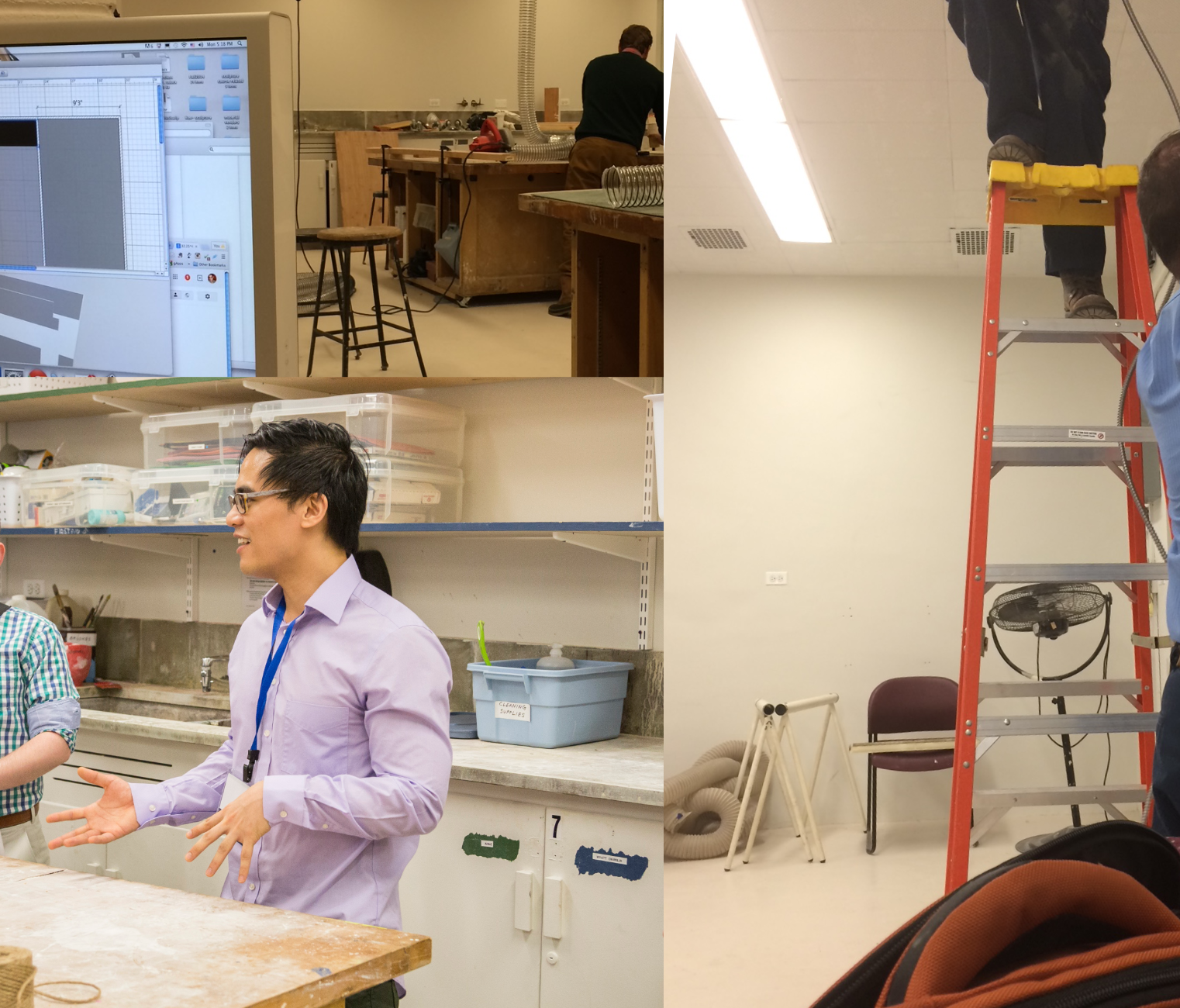

In collaboration with multiple faculty and staff, I was given significant collateral over the types of technologies, furniture, and so forth we could bring into the space. We worked on a renovation, taking down most existing furniture and deciding what materials and tools to keep so that contract work could be done to the space. Some of my planning involved creating mock 3d layouts of the space, proactively meeting and negotiating with stakeholders on key decisions, and ensuring the right kind of culture was established. Our initial layouts and plans would evolve over time.

Many art ed faculty leaders see technology as any other tool or material, akin to sculpture, and so forth. I sought to deliver that ethos to the environment. Thus, I came up with a goal: Help establish a new foundation around encouraging fusion of various sculpture materials inclusive of those created or manipulated by technology.

I also brought my values of creating openness. I aimed to create a wide variety of options for student experimentation that would be sustainable for years to come.

The name “Thingspace” came about through an impromptu discussion with one of the faculty; the faculty was fascinated by an exhibition where artists showcased mixed media “things” that were largely electronically manipulated. As the overseer of the new environment, I would encourage students to make digital and electronic “things” combined with other media.

Growth

Digital Fabrication Machines

I researched, collaborated with stakeholders and university staff, prepared requisitions, and built vendor relationships to not only ensure guests adhered to proper machine use but also to figure out ways guests could ignite their expressive capabilities.

Ranging from Adobe Illustrator, 3D modeling tools, and proprietary digital fabrication software, I trained myself in the machines so I could train others and set up a consistent and easy workflow so students could come in and do what they wanted.

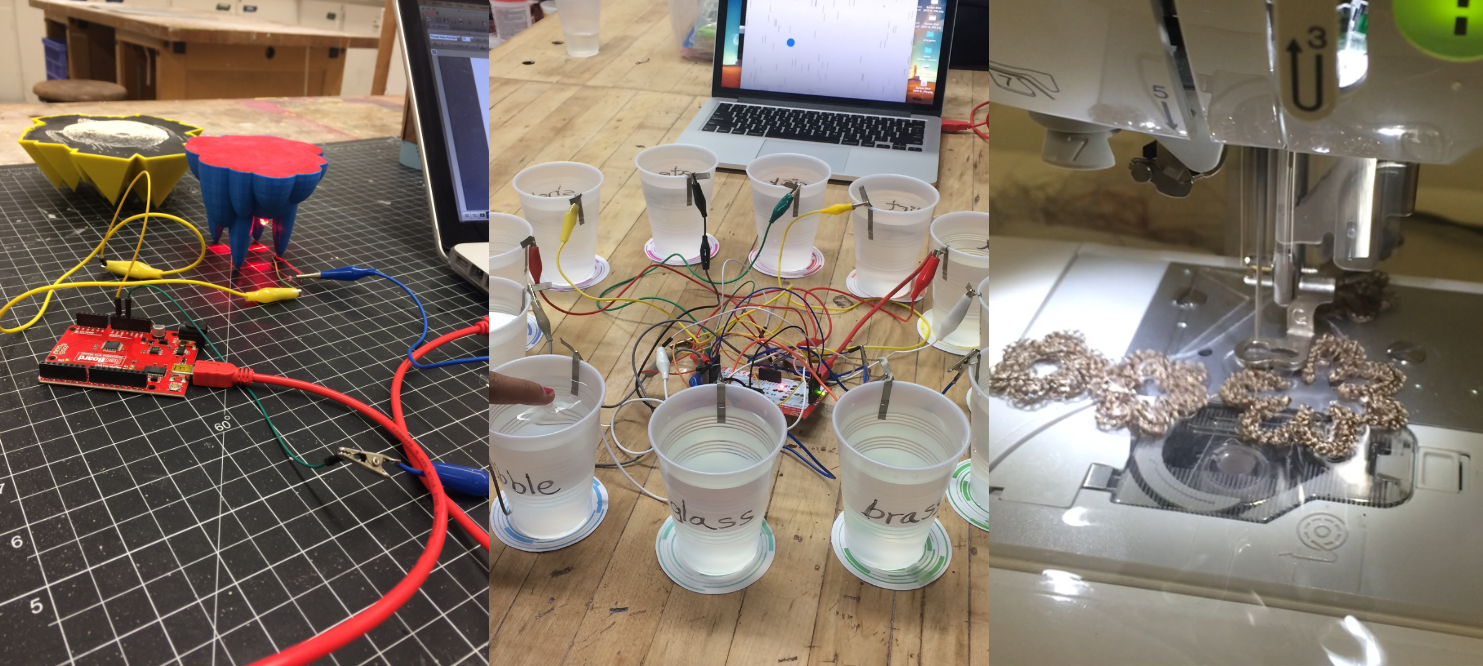

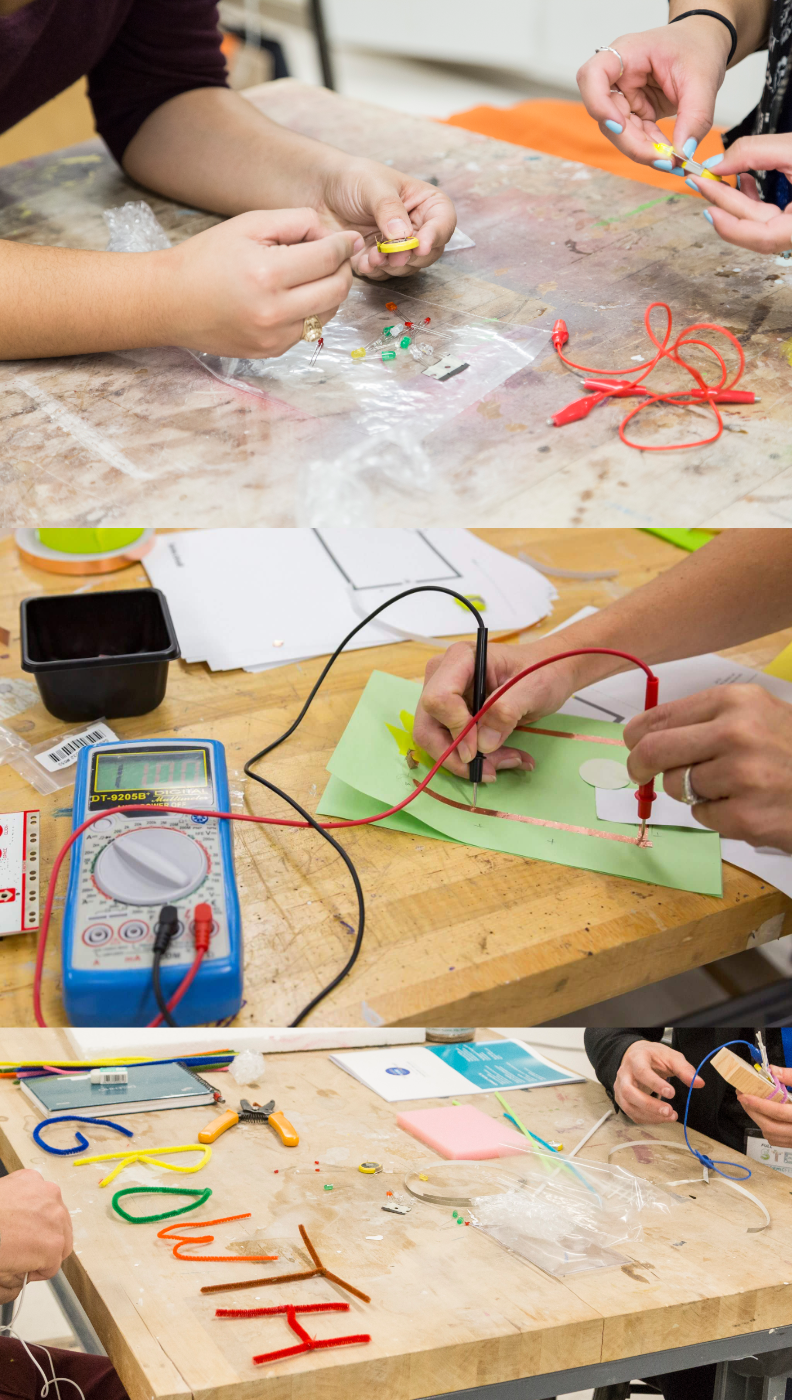

DIY Electronics

I also decided to instill more DIY electronics so that students could tinker with simple programming and hardware as well as integrate electronics with other materials. Experimental use of DIY electronics in educational space requires a wide assortment of inexpensive components, most of which should be reusable.

Workshops & Conference

I co-hosted many workshops and conference talks in the space all for the purposes of fusing digital fabrication with other material forms.

In-Person Support

Through in-person support, I conducted my own experimentations with media so I could have in-person samples and provide process-based suggestions to encourage students and faculty to realize ideas.

Sustainability

Training

Related to in-person support, I sought to provide long lasting training materials which could also be easily modified for future tools.

Outreach & Weblog

I aimed to develop a legacy and sustainable culture by investing resources in communication and future planning. In addition to hosting workshops, I created a weblog with helpful links and demonstrations and tips on using materials. For future staff members, I created documentation and organized digital files for clear and easier access.

Area Organization

I created distinct zones for different media types, so that Thingspace guests would be able to think of the space as a multimedia space. In addition to digital fabrication and electronics, media-centric zones included soft sculpture & plastic manipulation, woodworking, metal, hard materials sculpture, and crafts. By creating distinct zones for work, machines, classroom, material storage, and tools, I created structure and direction amidst the sheer number and variety of things from which Thingspace guests could interact and play.

Interest in the Thingspace to operate as a flexible, multifunctional space was another challenge. There were a large range of activities from art critiques, to executive presentations, to displaying work, to gatherings, to making work, to local workshops, and to classroom use; thus, the space needed to be shiftable while also having a sense of home.

Before and after of stools and tables (below black bar)

To further establish a sense of calm amidst the chaos, I selected new furniture or modified existing furniture to coincide with different zones. Later into the project, I collaborated with others such as an environment designer to support the installation of additional permanent fixtures to help with common guest flow and use.

Health and Safety

Finally, as an underground, multi-room space with assorted kinds of burning and spraying of materials from plastics to adhesives to electronics to wood, I pioneered analyses and proactively worked with health and safety colleagues to ensure a vibrant space in which guests could comfortably spend hours. This required doing research on determining, acquiring, and implementing different venthoods based on material and working area. Moreover, I ensured appropriate use and placement of safety equipment, development of proper machine use and cleaning protocols, and design of quality signage to provide clarity and respect to everyone’s time and mental resources.

Press

Some of the original versions of the above photos are taken by others, including Margaret Ferrec